Photo: Collected

Imagine you oversee an industrial or commercial facility where every piece of machinery and worker is critical. Now envision the chaos that ensues as pesky cottonwood seedlings clog your air intakes, suddenly disrupting your operations.

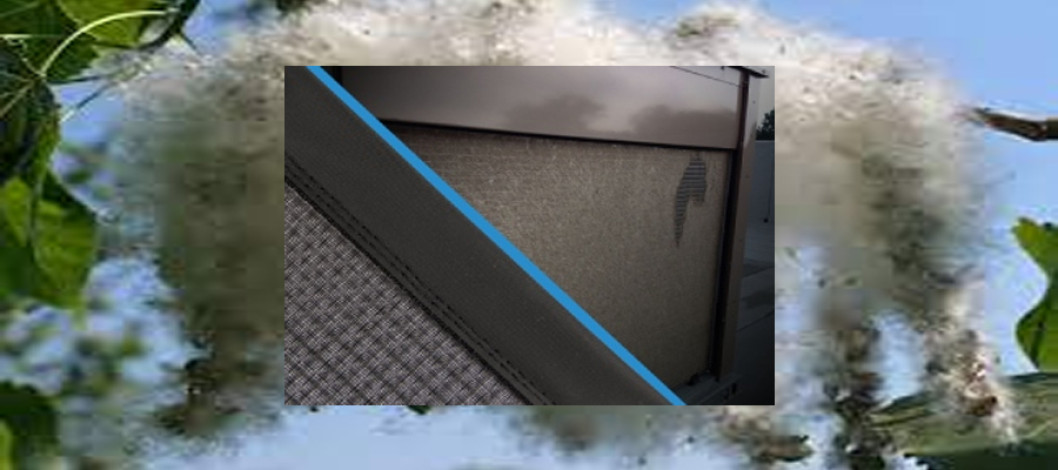

Despite their soft, fluffy appearance, cottonwood seedlings are more than just a nuisance—they can pose a significant threat to your manufacturing facility and your business. Even a gentle breeze can cause millions of tiny seedlings to travel through the air, getting sucked in at rates up to 23,000 cfm and blocking HVAC equipment strainers, fill material, fins, and filters. As a result, air quality and cooling are reduced, causing workers’ health and system processes to be compromised. Metal mesh filters can prevent cottonwood from entering HVAC units, but cleaning and maintaining the filters often becomes a time-consuming and labor-intensive job. However, there is a better cottonwood filter option—washable electrostatic filters. These filters prevent clogs and are a superior alternative to traditional metal mesh and other types of prefilters.

How Do Electrostatic Filters Work?

An electrostatic air filter uses static electricity to attract and trap various airborne particles. Electric charges are generated in the filter’s media when air flows through them. As particles suspended in the air stream flow through the filter, they pass through a section that charges the particles. This process is called ionization. Next, the charges pass through a section in the filter with an opposite charge, which draws the charged particles into the filter media, where they are captured, much like iron filings onto a magnet. There are numerous benefits that electrostatic air filters have over more traditional filters. See details.

Source: Online/NAN

Comment Now