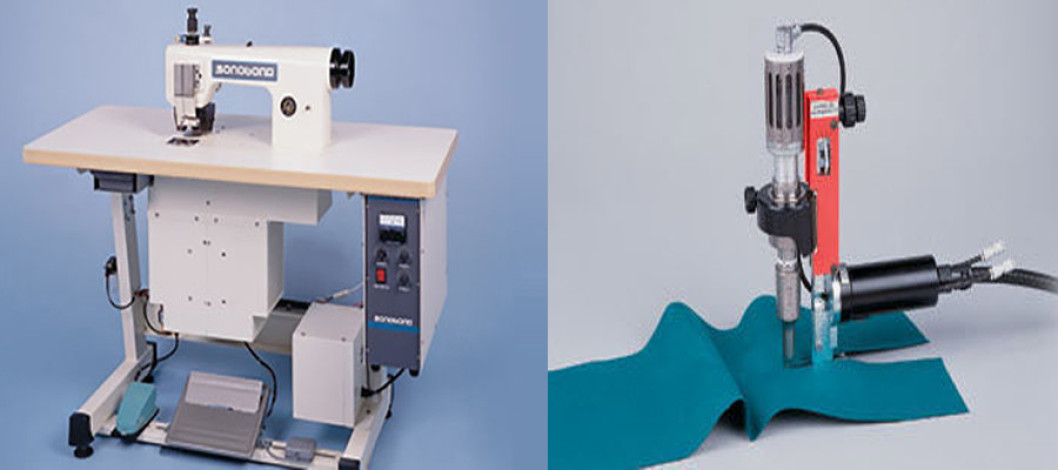

File Photo

Nonwovens are non-traditional fabrics and traditional cut-and-sew methods may not be the most effective way to produce end products using nonwovens. The onset of the pandemic and the need for personal protective equipment (PPE) in particular created increased interest in ultrasonic technologies those that use high-frequency sound waves to heat and plasticize man-made fiber nonwoven fabrics.

According to West Chester, Pa.-based Sonobond Ultrasonics, ultrasonic bonding technologies can quickly create strong, sealed edges and secure barrier seams that meet regulatory requirements. These high-quality bonds at pressure points create finished products without stitch holes, glue gaps, fraying, or unraveling. No thread is needed, and production tends to be fast for greater output.

Sonobond offers bonding, seaming, slitting, cutting and trimming equipment and often, more than one function may be performed on the same unit in a single step. Sonobond's SeamMaster Ultrasonic Sewing Machines are the company's most popular technology. SeamMaster offers continuous, patented rotary operation for strong, sealed, smooth and soft seams. According to the company, the machine can be used in a wide variety of assembly applications since more than one function may be performed at one time. For example, with the necessary tooling, the SeamMaster can bond, seam and trim in one quick step. Sonobond reports the speed is up to four times faster than when using a traditional sewing machine and up to 10 times faster than adhesive machines. The machine also is configured similarly to a traditional sewing machine, so minimal operator training is required to operate the SeamMaster.

Applications for Sonobond's technology in the medical nonwoven market include face masks; surgical gowns; disposable shoe, pillow and mattress covers; and lint-free wound dressings. Filtration products that may be made using Sonobond's ultrasonic technologies include pleated HVAC and HEPA filters; air, liquid and gas filters; heavy-duty filter bags; and spill clean-up cloths and oil containment booms.

To help a customer decide on the best technology for their application, Sonobond offers a free Ultrasonic Bonding Viability Test using the customer's nonwoven materials. The customer then has the opportunity to see the results and understand the capabilities of the available products.

Comment Now