File Photo

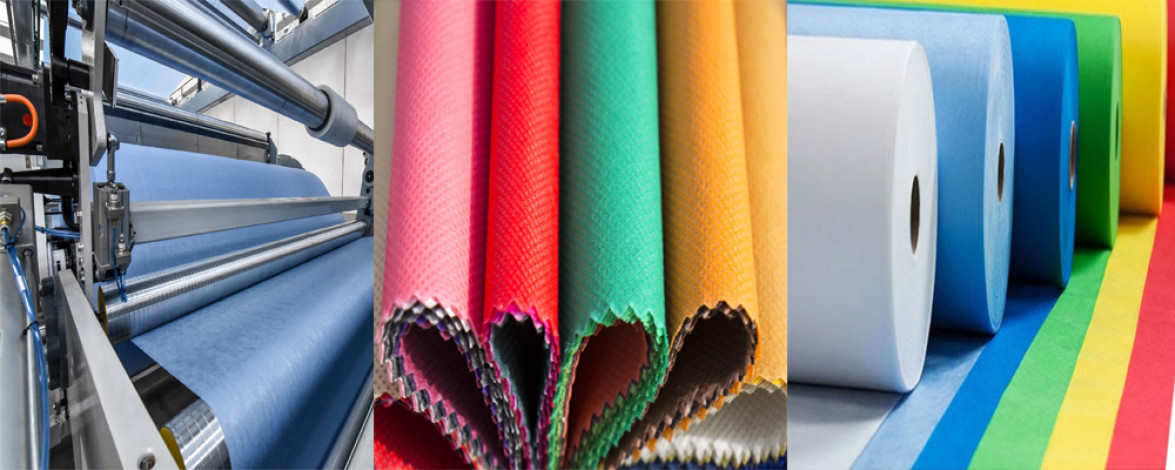

(1.) INTRODUCTION TO NONWOVENS

We know that nonwoven fabrics are one of the oldest and simplest textile fabrics. Its classic example is felt. The first well-documented discovery of felt dates back 3500-3000 BC. It was made from the hairs of various animals. The term Nonwoven fabrics was applied to new modern techniques, which were totally based on new principles, by the U.S.A. in 1965. "Non-woven fabrics" is being defined in different ways by different literatures; the term defined by "Textile oregano" in 1965 is as follows:

"Nonwoven fabrics are products made of parallel laid, cross, or randomly laid webs bonded with the application of adhesive or thermoplastic fibers under the application of heat and pressure."

In other words, nonwoven fabric can be simply defined as a fabric that can be produced by a variety of processes other than weaving and knitting. The nonwoven fabric properties depend on the following particulars to a great extent,

1. The choice of fibers

2. Technology which determines how the fibers are to be arranged

3. The bonding process and the bonding agent

Fabric properties of nonwovens range from crisp to soft-to-touch to harsh, impossible-to-tear to extremely weak. This leads to a wide range of end products such as nappies, filters, teabags, geotextiles, etc. some of which are durable and others are disposable. The first stage in the manufacturing process of nonwoven fabrics is the "production of the web" and another is the "bonding of the web by using several methods". Some of those (binding methods) are felting, adhesive bonding, thermal bonding, stitch bonding, needle punching, hydro-entanglement, and spin laying.

(2.) RAW MATERIALS

(2.1.) FIBROUS MATTER

The definition of nonwoven fabrics states that fibers are held together by a bonding agent to form a fabric. The art of choosing the right fiber to combine with the right binder by the most efficient process to obtain a desired fabric is the absolute goal of nonwoven manufacturing. Virtually all types of fibrous material can be used to make nonwoven bonded fabrics, the choice being dependent on:

* The required profile of the fabric

* The cost/ use ratio (cost-effectiveness)

* The demands of further processing

Source: Online/NNA

Comment Now