Photo: Collected

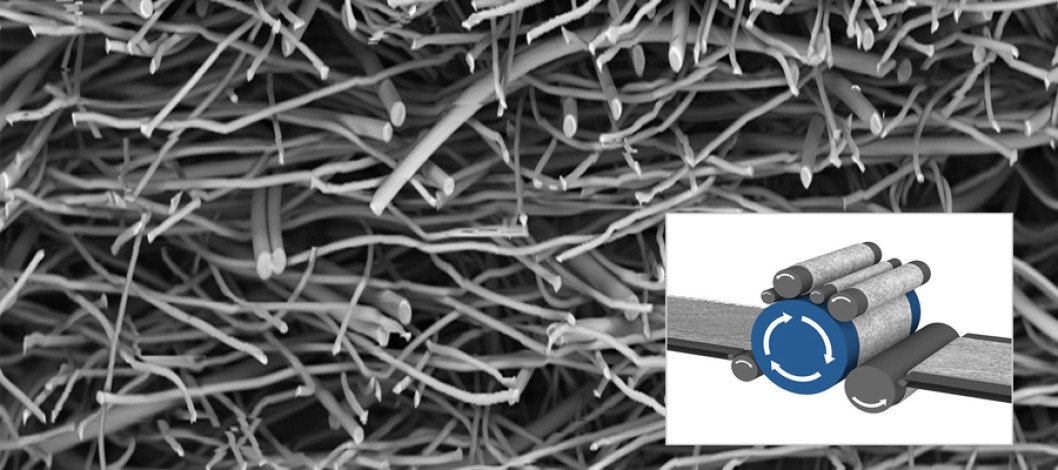

Drylaid nonwovens are made from staple fibers which the nonwoven manufacturers source in. Before processing the fibers are opened and mixed. The web formation takes place on roller cards with rotating workers and strippers.

To achieve high fabric weights crosslappers are used. Depending on the application, a large range of fibers can be used, such as synthetic fibers including viscose, natural fibers, glass fibers, or carbon fibers.

Source: Online/NAN

Comment Now